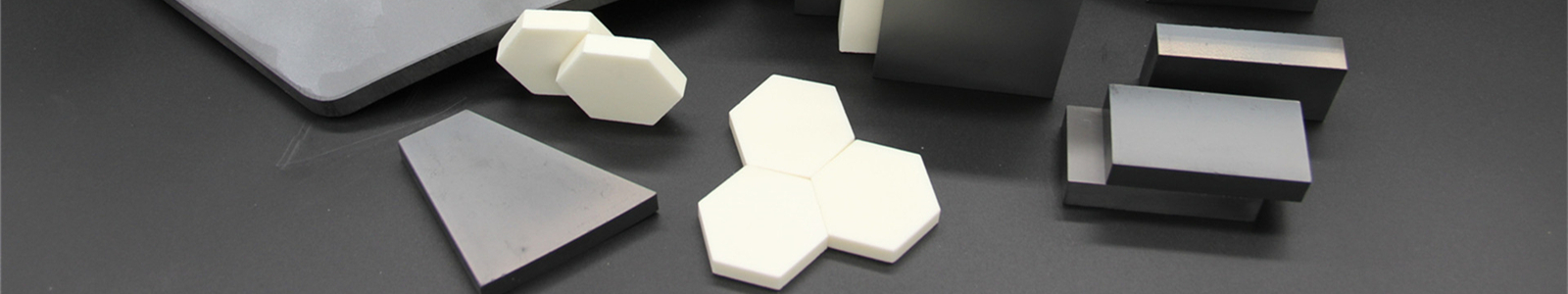

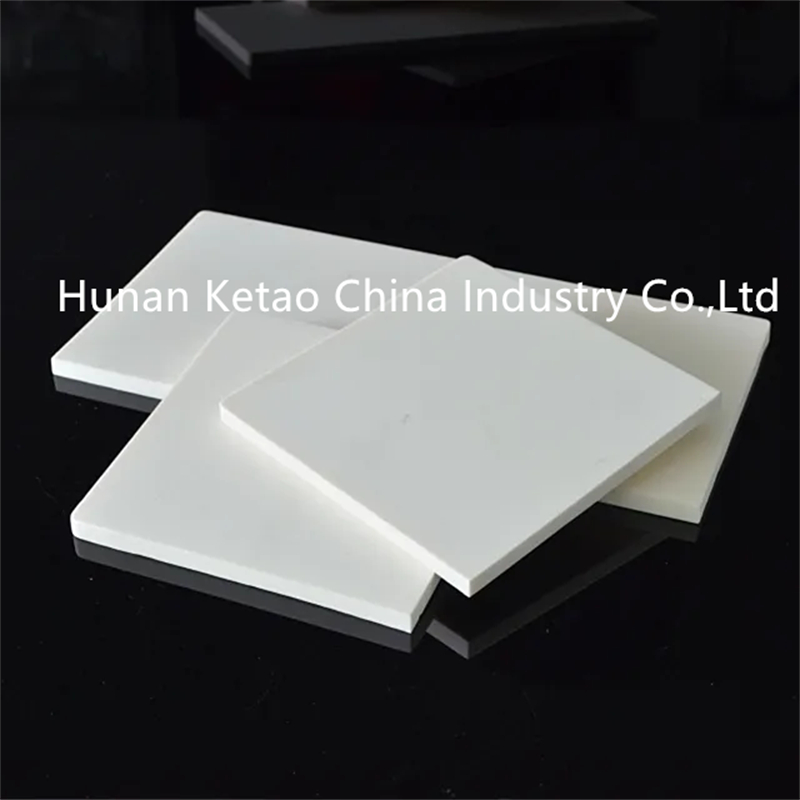

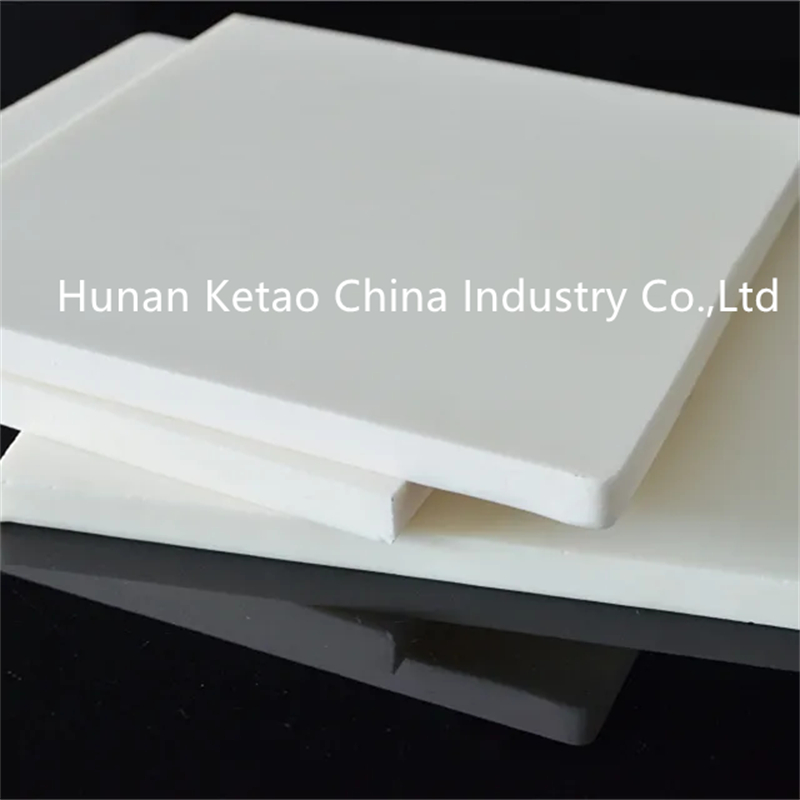

Alumina ceramic plate is a flat, thin piece of ceramic material made of alumina, which is a high-performance engineering material known for its excellent mechanical, electrical, and thermal properties. Alumina ceramic plates are highly resistant to wear, corrosion, and high temperatures, making them suitable for a wide range of applications in various industries.

Alumina ceramic plates can be made in various sizes, shapes, and thicknesses, and can be customized to meet specific requirements. They are often used as substrates for electronic components, as wear-resistant parts in mechanical systems, as heating elements in high-temperature applications, and as structural components in aerospace and defense industries.