KETAO Armor Ceramic Specification

| Property |

Reaction Bonded Silicon Carbide(RBSiC) |

Sintered Silicon Carbide(SSiC) |

Boron Carbide(B4C) |

Aluminum Oxide |

Bulk Density

(g/cm3) |

3.07±0.02 |

≥3.12 |

≥2.45 |

≥3.85 |

CMOR

(MPa) |

≥370 |

≥400 |

≥400 |

≥340 |

| Size |

Any size |

Any size |

Any size |

Any size |

Thickness

(mm) |

4.8~10.5 |

4.8~10.5 |

4.8~10.5 |

4.8~10.5 |

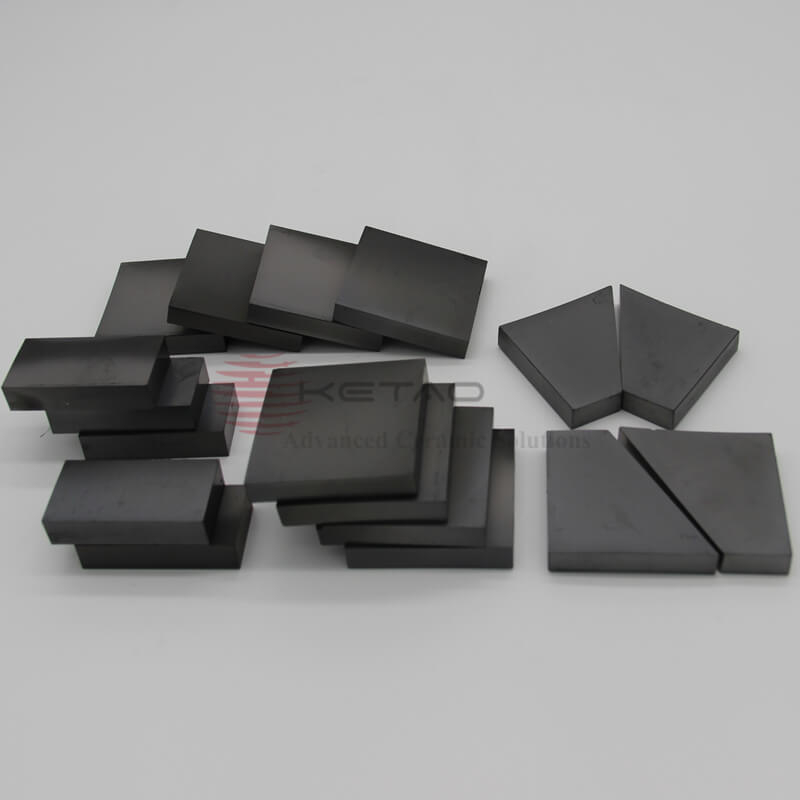

| Shape |

Single & Multi Curve |

Single & Multi Curve |

Single & Multi Curve |

Single & Multi Curve |

Existing Size In KETAO Workshop

| Curved |

Size(mm) |

Corner Cuts(mm) |

Thickness |

| Single-curved Monolithic Plate |

250*300 |

40*70 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

250*300 |

56*98 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

250*300 |

35*55 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

247*297 |

4*C20 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

220*270 |

50*80 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

220*270 |

50*50 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

220*270 |

4*R18 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

223*252 |

34*53 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

180*180 |

13*13 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

150*200 |

4*R30 |

4.8mm-10.5mm |

| Single-curved Monolithic Plate |

120*170 |

Right angle |

4.8mm-10.5mm |

| Curved |

Size(mm) |

Corner Cuts(mm) |

Thickness |

| Multi-Curved Monolithic Plate |

280*356 |

55*110 |

5.2mm-10.5mm |

| Multi-Curved Monolithic Plate |

268*312 |

53*122 |

5.2mm-10.5mm |

| Multi-Curved Monolithic Plate |

260*325 |

63*93 |

5.2mm-10.5mm |

| Multi-Curved Monolithic Plate |

250*300 |

60*80 |

4.8mm-10.5mm |

| Multi-Curved Monolithic Plate |

240*317 |

63*120 |

4.8mm-10.5mm |

| Multi-Curved Monolithic Plate |

221*298 |

55*110 |

4.8mm-10.5mm |

| Multi-Curved Monolithic Plate |

240*290 |

55*96 |

4.8mm-10.5mm |

| Multi-Curved Monolithic Plate |

238*286 |

55*95 |

4.8mm-10.5mm |

| Multi-Curved Monolithic Plate |

220*270 |

50*60 |

4.8mm-10.5mm |

| Multi-Curved Monolithic Plate |

195*245 |

41*50 |

4.8mm-10.5mm |

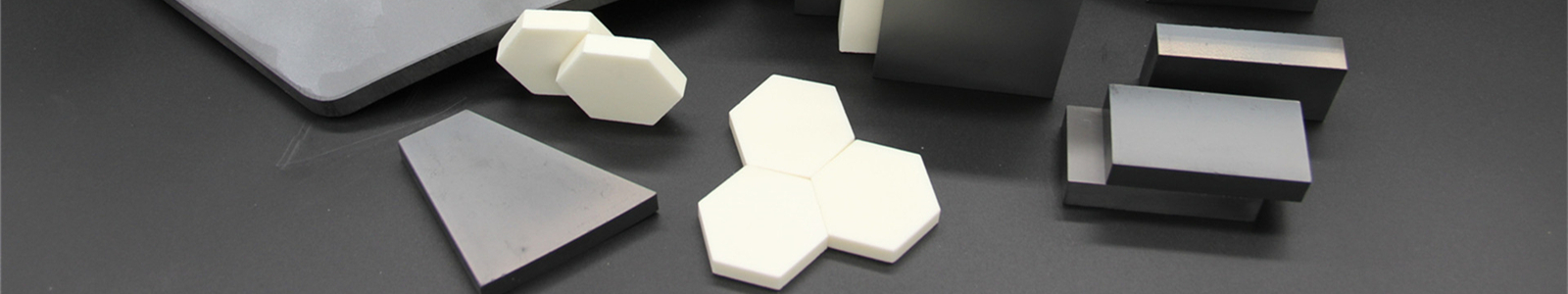

Who We Are

Focus on the ballistic protection ceramics over 20 years, Hunan Ketao China Industry CO.,Ltd(KETAO CERAMICS) is the world leader manufacturer in ballistic protection ceramics filed.

KETAO is a absolute advance protective ceramic manufacturer and developer. We are never compete with our customers. KETAO work with key partners to develop the most robust, cost-effective designs that provide advance ceramic solutions and set standards in terms of maintaining the tightest tolerances and reaching the highest level of ballistic protection.

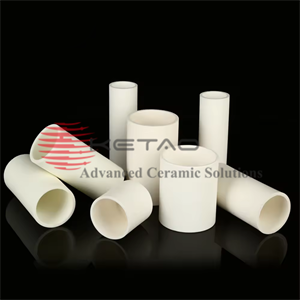

Based on the gigantic output capacity and extensive mass-production experience, KETAO provide top quality ceramic products with extremely cost-effective price, including Reaction Bonded Silicon Carbide(RBSiC), Sintered Silicon Carbide(SSiC), Boron Carbide(B4C), Alumina products which can meet the latest US, German and British body armor standards and are regularly tested in accredited international ballistic laboratories.

Why Choose KETAO

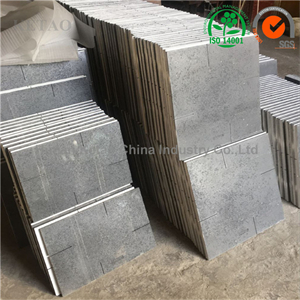

Huge Capacity

- Covers an area of 8,500 square meters factory

- 120 Employees

- 2700 Tons Pressing Machine- 3 Sets

- 900 Tons Pressing Machine- 15 Sets

- Shuttle Kilns-6

- Vacuum Sintering Furnaces-15

- Annual 1000 Tons of armor ceramics

Top Quality

First batch of KETAO customer is military, our workshop always keep the strictest military grade standards for our ceramic mass-produciton, there are several rigorous inspection in each production process, including packaging. Most of KETAO customers are recurring, among them defense integrators, contractors and fabricators from all of the world.

Best Services

Technician Team will provide the best ceramic armor solution according to your requirement.

Sales Team will reply to your inquiry, delivery or other questions with 24hours

Free Samples for your test

Delivery time will be around 15-25 working days based on the huge capacity.

There are almost all the size or shape of the mould in our workshop, it can save your mould cost.