- Home

- Product

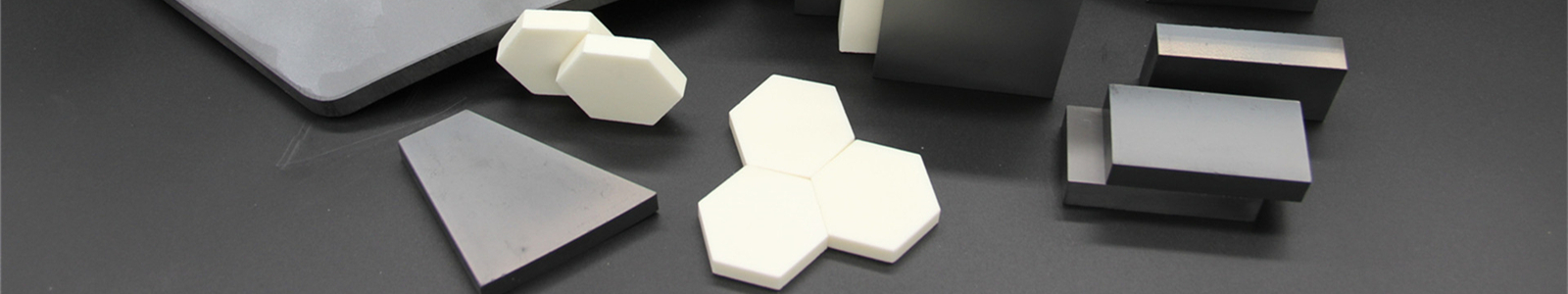

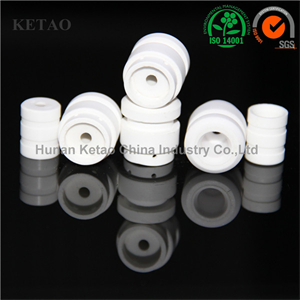

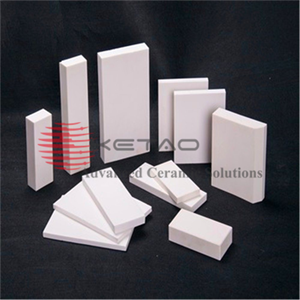

- Alumina Ceramics

- Alumina Ceramic Tube Alumina Ceramic Rod Alumina Ceramic Substrates Alumina Ceramic Disc Alumina Ceramic Plate Alumina Ceramic Roller Alumina Ceramic Crucible Alumina Ceramic Ring Alumina Ceramic Part

- About Us

- News

- Contact Us